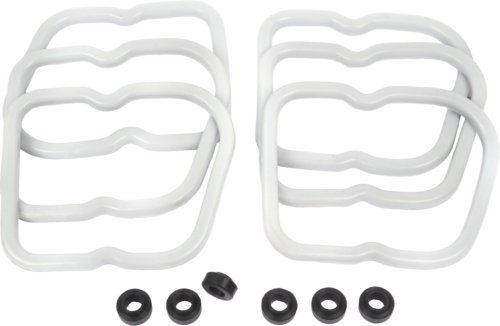

Oil Filler Assembly

MOQ : 100 Pieces

Oil Filler Assembly Specification

- For Use In

- Automotive Engines

- Temperature Range

- -20C to 120C

- Connecting Type

- Threaded

- Part Type

- Engine Oil Filler

- Operating System

- Manual Screw Fit

- Finish

- Smooth; Polished

- Noise Level

- 0 dB

- Surface Treatment

- Anodized

- Weight

- 0.15 kg

- Lubrication Type

- Oil

- Material

- Aluminum Alloy

- Color

- Silver

- Corrosion Resistant

- Yes

- Vehicle Type

- Passenger & Commercial Vehicles

- Working Life

- 35,000 hours

- Method

- Die Cast

- Model No

- OFA-39664

- Dimension (L*W*H)

- 5 x 5 x 6 cm

Oil Filler Assembly Trade Information

- Minimum Order Quantity

- 100 Pieces

- Payment Terms

- Letter of Credit (L/C), Telegraphic Transfer (T/T), Cash Advance (CA), Cash in Advance (CID), Cheque

- Supply Ability

- 50000 Pieces Per Day

- Delivery Time

- 1 Week

- Sample Available

- Yes

- Sample Policy

- Within a certain price range free samples are available

- Main Export Market(s)

- Western Europe, South America, Australia, North America, Eastern Europe, Africa, Central America, Middle East, Asia

- Main Domestic Market

- All India

About Oil Filler Assembly

An oil filler assembly is a component in an engine that is used to add or change the engine oil. It typically includes a filler cap, a dipstick, and a tube that connects the filler cap to the engine oil reservoir. The oil filler assembly plays an important role in maintaining proper engine lubrication, which is crucial for engine performance and longevity.

Oil filler assemblies are typically made from materials such as steel, aluminum, or plastic. They must be able to withstand the high temperatures and pressures generated by the engine oil, and they must be resistant to corrosion and other forms of wear and tear. The filler cap is usually threaded onto the oil filler tube to provide a secure seal.

If an oil filler assembly fails, it can cause a variety of problems, such as oil leaks, low oil pressure, and reduced engine performance. Therefore, it's important to inspect the oil filler assembly regularly and replace any components that show signs of wear or damage, such as cracks or leaks. A qualified mechanic can diagnose and repair any issues with the oil filler assembly or other components in the engine to ensure proper engine function and performance.

Superior Engineering for Universal Compatibility

Built to OEM standards, the OFA-39664 Oil Filler Assembly offers versatile fitting for most vehicle models, including passenger and commercial types. Its universal design and reliable threaded connection ensure straightforward integration with a wide variety of automotive engines. Enjoy seamless part replacement, regardless of make or model.

Long-Lasting, Heat-Resistant Construction

Manufactured using high-grade aluminum alloy and finished with a protective anodized coating, this oil filler assembly withstands operating temperatures from -20C up to 120C. It is engineered for a working life of 35,000 hoursmaking it a smart investment for vehicle owners and operators alike.

Easy, Secure Maintenance

The manual screw fit and vertical mounting system make installation straightforward, simplifying engine service routines. Its robust rubber gasket ensures a secure seal, reducing the risk of leaks and contamination, which contributes to smoother, cleaner engine operations.

FAQs of Oil Filler Assembly:

Q: How is the OFA-39664 Oil Filler Assembly installed on an engine?

A: The oil filler assembly features a threaded, manual screw fit designed for vertical mounting. It easily attaches to your engine without the need for specialized tools, ensuring a quick and secure installation process.Q: What benefits does the rubber gasket seal provide?

A: The rubber gasket offers reliable sealing to prevent oil leakage and protects against dust and water ingress, compliant with IP54 standards. This maintains the cleanliness and safety of your engine during operation.Q: When should I replace the oil filler assembly?

A: It is recommended to replace the OFA-39664 Oil Filler Assembly during every engine service cycle, ensuring optimal performance and longevity of both the assembly and the engine itself.Q: Where can the Oil Filler Assembly be used?

A: This component is designed for universal compatibility and can be used in both passenger and commercial vehicles, making it suitable for a broad range of automotive engines.Q: What is the process for maintaining the oil filler assembly?

A: Routine maintenance involves checking for wear on the gasket and ensuring the screw fit remains tight. During scheduled engine servicing, inspect and, if necessary, replace the assembly to keep the engine protected.Q: What are the advantages of its anodized, aluminum alloy construction?

A: The anodized aluminum alloy provides excellent corrosion resistance, durability, and heat resistance up to 120C, ensuring a smooth, polished appearance that lasts throughout the products service life.

Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

More Products in Engine Parts Category

Gasket for Intermediate Pipe

Minimum Order Quantity : 1 Piece

Dimension (L*W*H) : 115mm x 90mm x 5mm

Working Life : Up to 100,000 km

Material : HighTemperature Graphite Composite

Color : Metallic Grey

Valve Cover Gasket with Isolator Noise

Minimum Order Quantity : 100 Pieces

Dimension (L*W*H) : 340 mm x 110 mm x 10 mm

Working Life : Up to 60,000 km or 3 years

Material : Highstrength Rubber with Isolator

Color : Black

T - Bolt Hose Clamp (SLTB 72)

Minimum Order Quantity : 100 Pieces

Dimension (L*W*H) : 101.6 203.2 Millimeter (mm)

Working Life : 10 Years

Material : SS

Color : Silver

T - Bolt Hose Clamp (96 No.)

Minimum Order Quantity : 100 Pieces

Dimension (L*W*H) : 50.8 152.4 Millimeter (mm)

Working Life : 10 Years

Material : SS

Color : Silver

Send Inquiry

Send Inquiry