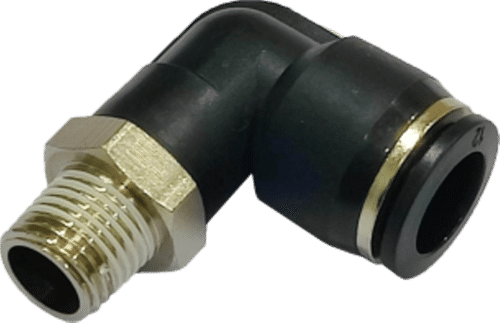

Lift Axle Connector Elbow 3718

Price 270 INR/ Piece

Lift Axle Connector Elbow 3718 Specification

- Lubrication Type

- Self-lubricating

- Dimension (L*W*H)

- 62mm x 26mm x 22mm

- Working Life

- 50,000+ Cycles

- Finish

- Smooth Polished

- Color

- Golden Yellow

- Part Type

- Connector Elbow

- Surface Treatment

- Nickel Plated

- Vehicle Type

- Heavy Duty Commercial Vehicles, Trucks, Trailers

- Temperature Range

- -40C to +120C

- Size

- Standard

- Noise Level

- Low

- Operating System

- Manual/Automatic Axle Lift Mechanism

- For Use In

- Automobile Lift Axle Systems

- Load Capacity

- Up to 12 Tonnes

- Material

- Brass

- Weight

- Approx 250g

- Connecting Type

- Elbow (90-degree) Connector

- Corrosion Resistant

- Yes

- Model No

- 3718

- Method

- Threaded Connection

- Product Type

- LIFT AXLE CONNECTOR

- Replacement Interval

- Every 5 Years

- Burst Pressure

- 30 Bar

- Thread Size

- M16 x 1.5

- Leakage Test

- Passed Under 10 Bar Pressure

- Port Type

- Push-to-Connect

- Mounting Style

- Panel/Bracket Mounted

- Pressure Rating

- Up to 10 Bar

- Application

- Air Suspension and Lift Axle Management

Lift Axle Connector Elbow 3718 Trade Information

- Minimum Order Quantity

- 1 Piece

- Payment Terms

- Cash in Advance (CID), Letter of Credit (L/C), Telegraphic Transfer (T/T), Cash Advance (CA), Cheque

- Sample Available

- Yes

- Sample Policy

- Within a certain price range free samples are available

- Main Export Market(s)

- Eastern Europe, North America, South America, Australia, Middle East, Western Europe, Central America, Asia, Africa

- Main Domestic Market

- Meghalaya, Manipur, Andhra Pradesh, Himachal Pradesh, Andaman and Nicobar Islands, Uttarakhand, Dadra and Nagar Haveli, Chandigarh, Delhi, Goa, Jharkhand, Karnataka, Daman and Diu, Lakshadweep, Assam, Arunachal Pradesh, Bihar, Gujarat, Jammu and Kashmir, Punjab, Pondicherry, Maharashtra, Mizoram, Rajasthan, Sikkim, Tamil Nadu, Telangana, Tripura, West Bengal, Nagaland, Uttar Pradesh, Madhya Pradesh, , South India, North India, East India, Haryana, Kerala, Central India, Odisha, West India, Chhattisgarh, All India

About Lift Axle Connector Elbow 3718

Outstanding Usage & Versatile Applications

The Lift Axle Connector Elbow 3718 is ideal for use in automobile lift axle systems, especially for trucks and trailers. Designed for panel or bracket mounting, this connector ensures optimized air suspension performance and secure, leak-proof connections. Its brass body, nickel-plated surface, and push-to-connect ports deliver reliability and corrosion resistance, making it suitable for challenging environments. The elbows smooth, polished finish and 90-degree design aid in maneuvering tight spaces and optimizing air flow in lift axle management systems.

Extensive Market Reach & Reliable Transportation Solutions

Lift Axle Connector Elbow 3718 caters to the main domestic market across India and is handed over for transport services internationally to key export markets. Renowned dealers, exporters, suppliers, and manufacturers benefit from regular supply ability and compliance with high standards. The efficient logistics process ensures products are transported safely and swiftly, meeting growing transportation demands for heavy-duty commercial vehicles. Whether you are a trader, wholesaler, or direct retailer, this connector elbow provides dependable delivery and wide market accessibility.

FAQs of Lift Axle Connector Elbow 3718:

Q: How is the Lift Axle Connector Elbow 3718 installed?

A: The Lift Axle Connector Elbow 3718 is designed for easy installation using a threaded connection and push-to-connect port. It can be panel or bracket mounted, facilitating swift and secure assembly in lift axle and air suspension systems.Q: What makes this connector beneficial for heavy-duty vehicles?

A: Its robust brass construction, 12-tonne load capacity, high pressure and burst pressure ratings, and resistance to corrosion make it ideal for enduring the rigorous demands of commercial trucks, trailers, and other heavy-duty vehicles.Q: When should the Lift Axle Connector Elbow 3718 be replaced?

A: For optimal performance and safety, the recommended replacement interval is every 5 years, or earlier if signs of wear or leakage are detected during routine maintenance.Q: Where can this connector be used effectively?

A: It is best suited for use in automobile lift axle systems, air suspension setups, and lift axle management within both manual and automatic axle lift mechanisms in heavy commercial vehicles.Q: What is the process for verifying its reliability?

A: Each connector elbow undergoes a stringent leakage test under 10-bar pressure, as well as burst testing at 30 bars, ensuring that every unit handed over meets outstanding quality and safety standards.Q: How does the connector enhance maintenance efficiency?

A: With its self-lubricating surface, smooth polished nickel plating, and low-noise operation, maintenance is simplified, minimizing downtime and extending the working life beyond 50,000 cycles.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in NEW ARRIVALS Category

EGR Pipe (Inner) TATA 1109

Price 2888 INR / Piece

Minimum Order Quantity : 1 Piece

Size : OEM Standard

Operating System : Engine Emission Recirculation

Connecting Type : Flanged/Clamped Connection

For Use In : TATA 1109 (Commercial Vehicle)

Leather Washer (80 mm) UNIVERSAL

Price 170 INR / Piece

Minimum Order Quantity : 1 Piece

Size : 80 mm

Operating System : Manual installation

Connecting Type : Press fit

For Use In : Universal application, especially in plumbing and sealing joints

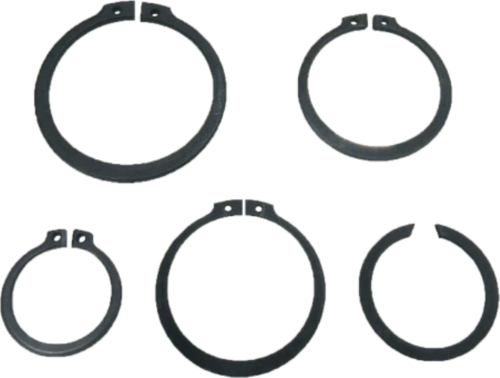

Main Shaft Circlip Set (Extra Thick) G. 750 BS IV

Price 350 INR / Piece

Minimum Order Quantity : 5 Pieces

Size : Standard G. 750 BS IV Main Shaft

Operating System : Manual Transmission Systems

Connecting Type : Slipon, Retaining Type

For Use In : Automobiles, G. 750 BS IV Gearbox Applications

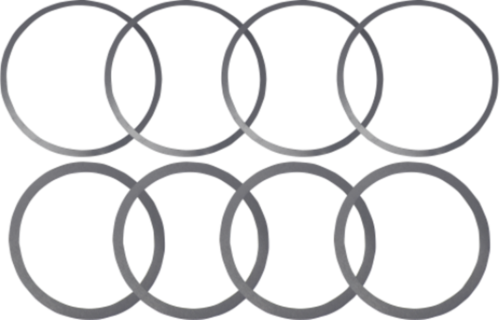

Gear Box Shims Kit G. 1150

Price 60 INR / Piece

Minimum Order Quantity : 10 Pieces

Size : Kit with assorted sizes (0.2 mm, 0.5 mm, 1 mm, 2 mm)

Operating System : Manual

Connecting Type : Insert fit

For Use In : Gear Box assemblies

Send Inquiry

Send Inquiry