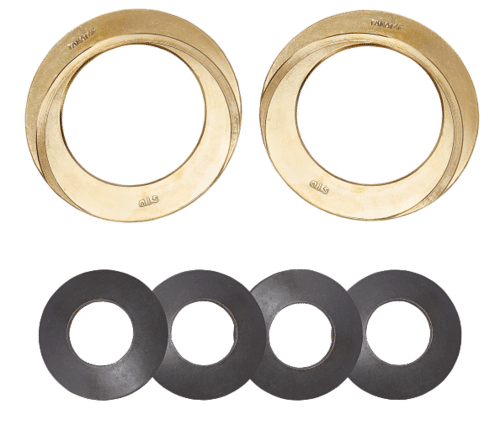

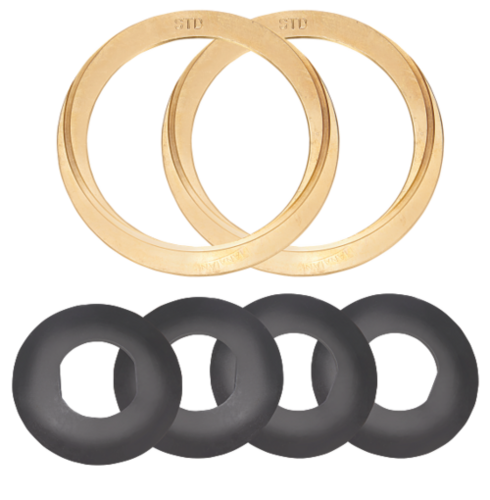

Differential Spider Washer (STD) A.L. Cargo/E Comet

Price 825 INR/ Set

Differential Spider Washer (STD) A.L. Cargo/E Comet Specification

- Size

- STD

- Method

- CNC Machined

- Working Life

- Long

- Product Type

- SPIDER WASHER

- Corrosion Resistant

- Yes

- Connecting Type

- Direct Fit

- For Use In

- A.L. Cargo, E Comet Differential

- Material

- Steel

- Part Type

- Differential Spider Washer

- Temperature Range

- -40 to 120C

- Color

- Silver

- Operating System

- Manual

- Weight

- Custom

- Vehicle Type

- Commercial Vehicle

- Noise Level

- Low

- Dimension (L*W*H)

- Standard OEM Size

- Lubrication Type

- Grease

- Model No

- STD

- Surface Treatment

- Zinc Plated

- Finish

- Smooth

- Load Capacity

- Heavy Duty

- Application

- Use in differential assembly for secure spider gear placement

- Packaging Type

- Box/Customized

- Manufacturing Standard

- OE Equivalent

- Installation

- Easy fitment

- Maintenance

- Low

- Rust Proof

- Yes

- Tolerance

- ±0.02 mm

- Hardness

- 45-48 HRC

- Compatibility

- A.L. Cargo, E Comet (Ashok Leyland)

- Shape

- Round with Central Bore

Differential Spider Washer (STD) A.L. Cargo/E Comet Trade Information

- Minimum Order Quantity

- 1 Set

- Payment Terms

- Telegraphic Transfer (T/T), Cash Advance (CA), Letter of Credit (L/C), Cash in Advance (CID), Cheque

- Sample Available

- Yes

- Sample Policy

- Within a certain price range free samples are available

- Main Export Market(s)

- Africa, Asia, Australia, South America, Eastern Europe, Western Europe, Middle East, Central America, North America

- Main Domestic Market

- All India

About Differential Spider Washer (STD) A.L. Cargo/E Comet

Features and Commercial Advantages

The Differential Spider Washer (STD) provides secure spider gear placement, essential for differential assemblies in commercial vehicles like A.L. Cargo and E Comet. With commanding hardness (45-48 HRC) and a tolerance of 0.02 mm, its outstanding CNC machined finish ensures precision and durability. Special features such as corrosion resistance, low noise, and smooth installation make it ideal for heavy-load goods transport applications, giving businesses peace of mind in machine reliability and operational efficiency.

Certifications and Market Distribution

Certified to OE Equivalent manufacturing standards, the Differential Spider Washer (STD) can be rapidly handed over to your location via reputable freight partners, ensuring swift and secure delivery. Serving the main domestic market across India, we extend our outstanding product through exporters, dealers, and wholesalers. Goods transport is streamlined from our FOB Port, reinforcing timely supply and reliability. Each washer comes securely packaged, enhancing value for commercial distribution and reducing downtime during installation.

FAQs of Differential Spider Washer (STD) A.L. Cargo/E Comet:

Q: How does the Differential Spider Washer (STD) benefit Ashok Leyland Cargo and E Comet vehicles?

A: This washer ensures secure spider gear placement in differential assemblies, reducing operational noise and prolonging component life in heavy-duty vehicles like A.L. Cargo and E Comet.Q: What is the installation process for the Differential Spider Washer (STD)?

A: The washer features a round shape with central bore and direct fit design, making installation easy for mechanics. No special tools are required and maintenance is minimal.Q: Where is this washer mainly distributed for commercial use?

A: It is supplied across India through dealers, wholesalers, and exporters, serving the broad commercial vehicle market, particularly for Ashok Leyland fleets.Q: When should this washer be replaced in a differential assembly?

A: Replacement is recommended during routine differential maintenance or when signs of wear, increased noise, or gear misalignment are noticed.Q: What certifications ensure the washers quality and reliability?

A: Manufactured to OE Equivalent standards and CNC machined for precision, the washer is certified for commercial use, providing peace of mind regarding durability and fitment.Q: How does the rust-proof and zinc-plated surface treatment benefit the washer?

A: The zinc-plated, rust-proof finish guards against corrosion and environmental damage, creating a longer service life and more dependable performance in commercial conditions.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Spider Washer Set Category

Differential Spider Washer (STD) 608

Price 420 INR / Set

Minimum Order Quantity : 1 Set

Temperature Range : 20C to 120C

Part Type : Differential Spider Washer

Material : Mild Steel (MS)

Model No : STD 608

Differential Spider Washer (1ST O/S)

Price 520 INR / Set

Minimum Order Quantity : 1 Set

Temperature Range : 30C to +120C

Part Type : Differential Spider Washer

Material : Highgrade Alloy Steel

Model No : 1ST O/S

Differential Spider Washer (6th O/S) 1613 TURBO

Price 705 INR / Set

Minimum Order Quantity : 1 Set

Temperature Range : 40C to 140C

Part Type : Differential Spider Washer

Material : Hardened Steel

Model No : 1613 TURBO

Thru Shaft Nut LPK 2516

Price 135 INR / Piece

Minimum Order Quantity : 1 Piece

Temperature Range : 20C to +250C

Part Type : Nut

Material : Alloy Steel

Model No : LPK 2516

Send Inquiry

Send Inquiry