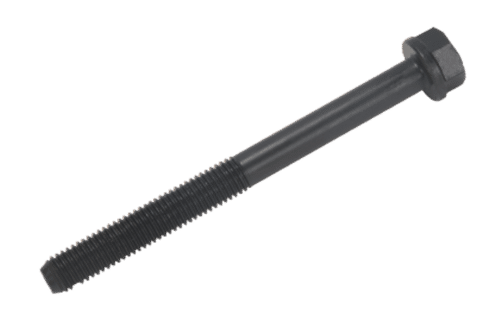

Connecting Rod Bolt

Price 80 INR/ Piece

Connecting Rod Bolt Specification

- Operating System

- Manual Fastening

- Surface Treatment

- Phosphated / Black Oxide

- For Use In

- Automobile Engine, Connecting Rod assemblies

- Temperature Range

- -40C to 200C

- Load Capacity

- Upto 1800 MPa Tensile Strength

- Noise Level

- Silent Operation

- Lubrication Type

- Oil Dipped

- Color

- Black

- Connecting Type

- Threaded Bolt

- Working Life

- Above 1 Million Cycles

- Weight

- 30-75 Grams

- Corrosion Resistant

- Yes

- Method

- Forged and Rolled Thread

- Material

- Alloy Steel

- Vehicle Type

- Cars/Trucks/Tractor Internal Combustion Engines

- Size

- M8, M10, M12 or as required

- Product Type

- FASTENERS GROUP

- Model No

- CRB-2237

- Finish

- Heat Treated, Precision Ground

- Part Type

- Connecting Rod Bolt

- Dimension (L*W*H)

- Standard, M8 x 1.25 x 45 mm (example)

- Packing Type

- Box / Bag

- Strength Class

- Class 10.9 / 12.9 Available

- Minimum Order Quantity

- 500 Pieces

- Application Industry

- Automotive, Heavy Machinery

- Hardness

- 38-44 HRC

- Head Shape

- Hex Head / Cap Head

- Thread Standard

- ISO Metric

- Tolerance

- +0.02 mm

Connecting Rod Bolt Trade Information

- Minimum Order Quantity

- 10 Pieces

- Payment Terms

- Cash in Advance (CID), Letter of Credit (L/C), Cash Advance (CA), Telegraphic Transfer (T/T), Cheque

- Sample Available

- Yes

- Sample Policy

- Within a certain price range free samples are available

- Main Domestic Market

- All India

About Connecting Rod Bolt

Premium Features & Application Areas of Connecting Rod Bolt

Our Connecting Rod Bolt stands out for its robust surface treatmentphosphated or black oxidefor lasting corrosion protection. It showcases a hex/cap head for easy application and is perfectly suited to automobile engines, connecting rod assemblies, and heavy machinery industries. The bolts customizable dimensions, top-grade strength (upto 1800 MPa tensile), and reliability in extreme temperatures (-40C to 200C) make it indispensable in applications requiring silent, precise operation and superior fatigue resistance.

Stock Ready Supply, Fast Dispatch, and Hassle-Free Samples

Rely on our stock-ready inventory of Connecting Rod Bolts for immediate requirements. With capabilities to handle bulk orders and a minimum order quantity of 500 pieces, we ensure quick dispatch to meet your urgent production timelines. Samples are available for valuation and quality verification. A transparent sample policy allows clients to test compatibility before committing to large purchases, supporting dealers, traders, and wholesalers across India with efficient sourcing and delivery.

FAQs of Connecting Rod Bolt:

Q: How does the connecting rod bolt enhance engine performance?

A: The connecting rod bolt ensures stable, high-strength fastening between connecting rods and internal combustion engine parts, resulting in improved durability, silent operation, and consistent engine performance over long cycles.Q: What is the process used to manufacture the CRB-2237 bolt?

A: CRB-2237 is manufactured using the forging method and rolled thread technique, followed by heat treatment and precision grinding, resulting in a superior, long-lasting, and corrosion-resistant product.Q: Where can these connecting rod bolts be used effectively?

A: These bolts are best suited for automotive engines, trucks, tractors, and heavy machinery where high load tolerance, tight dimensional control, and resistance to tough operating conditions are required.Q: When should a connecting rod bolt be replaced?

A: A connecting rod bolt should be replaced during engine overhauls, after one million cycles, or if inspection reveals wear, stretching, or damage to maintain optimal safety and performance.Q: What benefits does a phosphated or black oxide surface provide?

A: Phosphated or black oxide surfaces enhance the bolts corrosion resistance, reduce friction during installation, and extend service life in harsh environments and high-stress applications.Q: How can I order a sample for quality assessment?

A: Contact our sales team or associated dealers to request a sample under our transparent sample policy; we prioritize quick dispatch for efficient valuation and decision-making.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in FASTENERS GROUP Category

Cylinder Head Bolt (120 mm)

Price 100 INR / Piece

Minimum Order Quantity : 10 Pieces

Method : Cold Forged

Dimension (L*W*H) : 120 mm (Length) x 10 mm (Diameter) x 10 mm (Head Height)

Material : Alloy Steel

Part Type : Cylinder Head Bolt

Lift Axle Bolt M24 X 150

Price 425 INR / Piece

Minimum Order Quantity : 1 Piece

Method : Hot Forged

Dimension (L*W*H) : 150mm (Length)

Material : Alloy Steel

Part Type : Axle Bolt

Starter Bolt

Price 75 INR / Piece

Minimum Order Quantity : 10 Pieces

Method : Cold Forged

Dimension (L*W*H) : M10 x 1.25 x 80 mm

Material : Mild Steel

Part Type : Starter Bolt

Lift Axle Bolt M24 X 190

Price 485 INR / Piece

Minimum Order Quantity : 1 Piece

Method : Cold Forged

Dimension (L*W*H) : M24 x 190 mm (Diameter x Length)

Material : High Tensile Steel

Part Type : Lift Axle Bolt

Send Inquiry

Send Inquiry

Call Me Free

Call Me Free