Brake Shoe Return Spring 1613/2515

Price 130 INR/ Piece

Brake Shoe Return Spring 1613/2515 Specification

- Part Type

- Brake Shoe Return Spring

- Temperature Range

- -40C to +180C

- Model No

- 1613/2515

- Noise Level

- Silent/Minimal

- Dimension (L*W*H)

- 161 mm x 25 mm x 15 mm

- For Use In

- Brake Shoe Assembly for Heavy Vehicles

- Corrosion Resistant

- Yes

- Surface Treatment

- Phosphated and Oiled

- Method

- Cold Coiled

- Vehicle Type

- Truck/Commercial Vehicle

- Product Type

- BRAKE GROUP

- Operating System

- Mechanical

- Material

- High-Quality Spring Steel

- Load Capacity

- Up to 120 kg

- Color

- Metallic Grey

- Finish

- Anti-Corrosive Coating

- Weight

- 120 g

- Lubrication Type

- Pre-lubricated

- Connecting Type

- Hooked Ends

- Size

- Standard OE Specification

- Working Life

- Over 100,000 Cycles

Brake Shoe Return Spring 1613/2515 Trade Information

- Minimum Order Quantity

- 6 Pieces

- Payment Terms

- Letter of Credit (L/C), Telegraphic Transfer (T/T), Cash Advance (CA), Cash in Advance (CID), Cheque

- Sample Available

- Yes

- Sample Policy

- Within a certain price range free samples are available

- Main Export Market(s)

- Eastern Europe, Australia, North America, South America, Western Europe, Middle East, Central America, Asia, Africa

- Main Domestic Market

- Delhi, Chandigarh, Goa, Andaman and Nicobar Islands, Uttarakhand, Daman and Diu, Lakshadweep, Bihar, Jharkhand, Mizoram, Himachal Pradesh, Dadra and Nagar Haveli, Nagaland, Jammu and Kashmir, Madhya Pradesh, Meghalaya, Manipur, Pondicherry, Rajasthan, Sikkim, Tamil Nadu, Telangana, Tripura, West Bengal, All India, Uttar Pradesh, , South India, East India, Andhra Pradesh, Assam, Arunachal Pradesh, Haryana, Maharashtra, Gujarat, Karnataka, North India, Punjab, Kerala, Central India, Odisha, West India, Chhattisgarh

About Brake Shoe Return Spring 1613/2515

Highlighted Applications Across Surfaces and Plants

The Brake Shoe Return Spring 1613/2515 is tailored for use in heavy-duty truck brake assemblies, specifically Tata 1613/2515 models. Its sturdy metallic grey finish and phosphated, oiled surface treatment excel in abrasive, high-friction media such as steel and iron drum brakes. Ideal for automotive plants and commercial vehicle service centers, this spring ensures extended working life in demanding environments while maintaining optimal mechanical integrity and safety performance.

Global Export and Competitive Market Valuation

FOB port options for the Brake Shoe Return Spring 1613/2515 facilitate swift international shipping. Its sale price reflects superior material quality and a meticulous manufacturing process. Main export markets cover the Middle East, Africa, and Southeast Asia, while the primary domestic market is robust across India. Each purchase order is smoothly processedcatering to dealers, exporters, and wholesalersmaking it a competitively valued component for both local and international buyers.

FAQs of Brake Shoe Return Spring 1613/2515:

Q: How does the Brake Shoe Return Spring 1613/2515 enhance truck brake performance?

A: It maintains consistent tension and alignment during braking cycles, ensuring optimal retraction of the brake shoes and providing silent, effective braking for heavy vehicles.Q: What is the recommended replacement interval for this spring?

A: The replacement interval should follow the manufacturers guidance, typically during routine maintenance or whenever reduced tension or visible wear is detected in the brake assembly.Q: Where can I buy the Brake Shoe Return Spring 1613/2515 online?

A: You can conveniently buy this part from authorized online retailers, dealers, and suppliers catering to commercial vehicle components within India and major global markets.Q: What benefits does the high-quality spring steel construction offer?

A: It delivers superior tensile strengthover 1200 MPaalong with high resistance to wear and corrosion, contributing to a prolonged working life and reliable mechanical performance.Q: What is the process used to manufacture the Brake Shoe Return Spring 1613/2515?

A: The spring is produced using CNC precision winding and cold coiling methods, which ensure dimensional accuracy and a consistent spring rate matching OEM standards.Q: How effective is the spring under varying temperature conditions?

A: It operates reliably within a wide temperature range, from -40C to +180C, maintaining strength and elasticity in diverse environmental conditions.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Brake Parts Category

Brake Shoe Spring YORK

Price 60 INR / Piece

Minimum Order Quantity : 10 Pieces

Dimension (L*W*H) : Custom as per model

Material : Steel

Working Life : 100,000 cycles (approx.)

Brake Shoe Retaining Spring BHARAT BENZ

Price 140 INR / Piece

Minimum Order Quantity : 1 Piece

Dimension (L*W*H) : 120mm x 15mm x 15mm

Material : High Grade Steel

Working Life : Up to 50,000 km

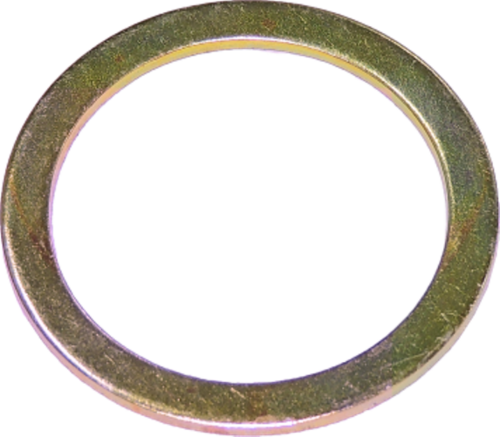

Brake Cam Washer Big (1 mm) 2515/2518

Price 10 INR / Piece

Minimum Order Quantity : 50 Pieces

Dimension (L*W*H) : External Diameter 25 mm, Internal Diameter 15 mm, Thickness 1 mm

Material : Highgrade Steel

Working Life : Over 50,000 cycles

Brake Shoe Retaining Spring

Minimum Order Quantity : 100 Pieces

Dimension (L*W*H) : 50mm x 8mm x 3mm

Material : High Carbon Steel

Working Life : Over 50,000 Cycles

Send Inquiry

Send Inquiry