Axle Plate (Cut type) 2515

Price 410 INR/ Piece

Axle Plate (Cut type) 2515 Specification

- Operating System

- Manual Axle Assembly

- Connecting Type

- Bolt-On

- Finish

- Smooth

- Dimension (L*W*H)

- 220mm x 140mm x 8mm

- Part Type

- Axle Plate

- For Use In

- Auto Rickshaw / Three Wheeler

- Load Capacity

- Up to 500 kg

- Material

- Mild Steel

- Size

- Standard as per OE specification

- Product Type

- REAR AXLE GROUP

- Corrosion Resistant

- Yes

- Method

- CNC Cut Type

- Model No

- 2515

- Color

- Black

- Surface Treatment

- Powder Coated

- Noise Level

- Low

- Working Life

- Over 50,000 km

- Temperature Range

- -20C to +70C

- Vehicle Type

- Three Wheeler / Auto Rickshaw

- Weight

- Approx. 3.5 kg

- Lubrication Type

- Grease Applied

- Replacement Cycle

- 2-3 years under normal use

- Compliance

- ISO/TS 16949 Certified

- Impact Resistance

- High

- Tensile Strength

- > 400 MPa

- Hole Pattern

- Standardized for multiple axle fits

- Packaging Type

- Individual Poly Bag & Box

- Mounting Holes

- 8 Pre-drilled Holes

- Edge Profile

- Deburred and Smooth Finished

- Customization

- Available on Request

- Hardness

- 175-200 HB

Axle Plate (Cut type) 2515 Trade Information

- Minimum Order Quantity

- 1 Piece

- Payment Terms

- Letter of Credit (L/C), Telegraphic Transfer (T/T), Cash in Advance (CID), Cash Advance (CA), Cheque

- Sample Available

- Yes

- Sample Policy

- Within a certain price range free samples are available

- Main Export Market(s)

- Middle East, Asia, Australia, South America, North America, Eastern Europe, Western Europe, Africa, Central America

- Main Domestic Market

- Himachal Pradesh, Daman and Diu, Lakshadweep, Andaman and Nicobar Islands, Uttarakhand, Chandigarh, Delhi, Mizoram, Dadra and Nagar Haveli, Bihar, Meghalaya, Goa, Haryana, Jammu and Kashmir, Jharkhand, Karnataka, Madhya Pradesh, Maharashtra, Manipur, Punjab, Tripura, Nagaland, West Bengal, Kerala, Gujarat, All India, Pondicherry, Rajasthan, Tamil Nadu, Sikkim, Telangana, , South India, East India, West India, Assam, Arunachal Pradesh, Uttar Pradesh, North India, Andhra Pradesh, Central India, Odisha, Chhattisgarh

About Axle Plate (Cut type) 2515

Optimized for Three Wheeler Usage: Durable, Versatile, and Efficient

The Axle Plate (Cut type) 2515 is designed specifically for auto rickshaws and three-wheelers, offering a deburred, smooth finish for reduced noise and optimal performance. Fabricated from mild steel, its high impact resistance and powder-coated surface boost longevity. With standardized, pre-drilled holes and a bolt-on configuration, installation is streamlined. This plate delivers stellar operational efficiency under manual axle assemblies, supporting a load capacity of up to 500 kg and exceeding 50,000 km working life with minimal maintenance demands.

Packaging, Supply, and Transportation: Secured and Reliable Delivery

Each Axle Plate 2515 is individually packaged in a poly bag and box, ensuring unassailable protection during transport and handling. Goods transport valuation is enhanced by these robust packaging protocols, minimizing the risk of damage and streamlining inventory management. With a highly responsive supply ability, orders are expertly managed from Indias principal FOB ports for timely dispatch. This process upholds the stellar reliability and condition of each axle plate delivered to dealers, distributors, and end-users alike.

FAQs of Axle Plate (Cut type) 2515:

Q: How does the Axle Plate (Cut type) 2515 ensure cost-effective maintenance for vehicle owners?

A: With an expected replacement cycle of 23 years under normal use and a working life of over 50,000 km, the Axle Plate 2515 minimizes maintenance frequency and expenses, leading to significant and instant savings for vehicle owners.Q: What makes the Axle Plate 2515 suitable for multiple axle configurations?

A: The standardized hole pattern with 8 pre-drilled mounting holes allows the plate to fit a variety of three-wheeler and auto rickshaw axle assemblies, ensuring versatile application and redeeming the need for specialized components.Q: When should the Axle Plate (Cut type) 2515 be replaced in a standard operating environment?

A: Replacement is generally recommended every 23 years under normal operating conditions, but may vary based on usage intensity and environmental factors to maintain unassailable performance.Q: What are the primary features that enhance the durability of this axle plate?

A: High tensile strength, powder-coated corrosion resistance, deburred and smooth edges, and usage of first-string mild steel ensure the plate withstands harsh conditions while staying structurally sound.Q: Where is the Axle Plate (Cut type) 2515 best sourced from?

A: It is best sourced directly from reputable dealers, exporters, manufacturers, retailers, suppliers, traders, or wholesalers in India, ensuring authenticity and stellar quality assurance.Q: What are the benefits of the axle plates packaging for transportation and valuation?

A: The individual poly bag and box packaging safeguard each unit during goods transport, reducing damage risk and supporting a higher valuation upon delivery.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Rear Axel Parts Category

Axle Plate 1109

Price 155 INR / Piece

Minimum Order Quantity : 1 Piece

Surface Treatment : Powder Coated

Part Type : Axle Plate

Noise Level : Silent Operation

Color : Black

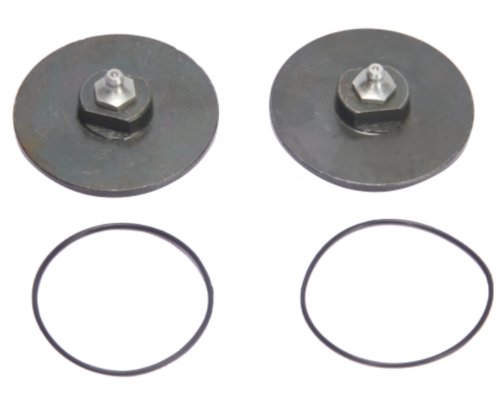

King Pin Cap Set of 2 Pcs. 3118

Price 590 INR / Set

Minimum Order Quantity : 1 Set

Surface Treatment : Zinc Plated

Part Type : King Pin Cap Set

Noise Level : Low

Color : Silver / Grey

Lock Washer 407

Price 30 INR / Piece

Minimum Order Quantity : 10 Pieces

Surface Treatment : Zinc Plated

Part Type : Lock Washer

Noise Level : Silent

Color : Silver

Rear Hub Spacer 2518/3118/U TRUCK

Price 1025 INR / Piece

Minimum Order Quantity : 1 Piece

Surface Treatment : Zinc plated / Phosphated

Part Type : Rear Hub Spacer

Noise Level : Silent Operation

Color : Metallic Grey

Send Inquiry

Send Inquiry