Air Chamber Assembly with hardware LPK 2516

Price 1050 INR/ Set

Air Chamber Assembly with hardware LPK 2516 Specification

- Temperature Range

- -30C to +80C

- Part Type

- Brake chamber assembly

- Connecting Type

- Threaded and bolted hardware

- Load Capacity

- Supports up to 16 tons

- Corrosion Resistant

- Yes

- Working Life

- 100,000 cycles

- Operating System

- Air pressure actuated

- Method

- Precision manufacturing

- Dimension (L*W*H)

- 230mm x 105mm x 110mm

- Model No

- LPK 2516

- Surface Treatment

- Electroplated and painted

- Lubrication Type

- Factory pre-lubricated

- For Use In

- Automobile air brake system

- Product Type

- AIR CHAMBER ASSEMBLY WITH HARDWARE

- Noise Level

- <68 dB

- Finish

- Smooth & corrosion resistant

- Color

- Black & Silver

- Vehicle Type

- Heavy-duty commercial vehicles

- Size

- Standard fit for LPK 2516

- Weight

- 3.8 kg

- Material

- High-grade steel and rubber composites

- Replacement Interval

- As per OEM recommendations

- Seal Type

- Double-sealing diaphragm

- Compatibility

- Fits LPK 2516 and equivalent chassis

- Compliance

- OEM standards & ISO/TS certified

- Installation Time

- Approximately 25 minutes

- Shock Resistance

- Tested to withstand up to 200G

- Mounting Orientation

- Vertical or Horizontal

- Maintenance Interval

- Every 12 months or 60,000 km

- Packaging Type

- Cardboard box with protective lining

- Operating Pressure

- 6 to 10 Bar

- Hardware Included

- Mounting brackets, bolts, nuts, washers

Air Chamber Assembly with hardware LPK 2516 Trade Information

- Minimum Order Quantity

- 1 Set

- Sample Available

- Yes

- Sample Policy

- Within a certain price range free samples are available

- Main Domestic Market

- All India

About Air Chamber Assembly with hardware LPK 2516

Competitive Advantages and Suitable Commercial Applications

The Air Chamber Assembly with hardware (LPK 2516) is engineered for heavy-duty commercial vehicles, making it suitable for intense operational requirements. Its outstanding shock resistance, double-sealing diaphragm, and redoubtable durability provide assurance in demanding conditions. Ideal for dealers, manufacturers, and fleets, it assures improved safety and minimized downtime. Competitive advantages like factory pre-lubrication, rapid installation, and precision engineering make it a preferred component within high-load automobile brake systems.

Main Domestic Market and Transaction Details

Serving the Indian market, this air chamber assembly is readily available with stock ready for prompt shipment. Samples can be delivered upon request, with charges as per company policy. Flexible payment terms are provided for added convenience. Whether you are a retailer or wholesaler, each unit is securely packaged in a protective cardboard box and delivered nationwide, ensuring peace of mind and efficient order fulfillment.

FAQs of Air Chamber Assembly with hardware LPK 2516:

Q: How long does installation of the Air Chamber Assembly with hardware LPK 2516 take?

A: Installation is straightforward, typically requiring approximately 25 minutes thanks to the inclusion of mounting brackets, bolts, nuts, and washers.Q: What are the main benefits of the double-sealing diaphragm design?

A: The double-sealing diaphragm enhances the chambers reliability, providing superior sealing performance and reducing the risk of air leakage in commercial brake systems.Q: When should I schedule maintenance for this air chamber assembly?

A: It is recommended to perform maintenance every 12 months or after 60,000 km of usage to ensure optimal performance and extended service life.Q: Where is this product commonly used?

A: This air chamber assembly is principally used in heavy-duty commercial vehicles fitted with air brake systems, including LPK 2516 and equivalent chassis models.Q: What process ensures the durability and pristine finish of this assembly?

A: The precision manufacturing process, combined with electroplating and painting, delivers a smooth, corrosion-resistant surface, supporting a working life of up to 100,000 cycles.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Differential Parts Category

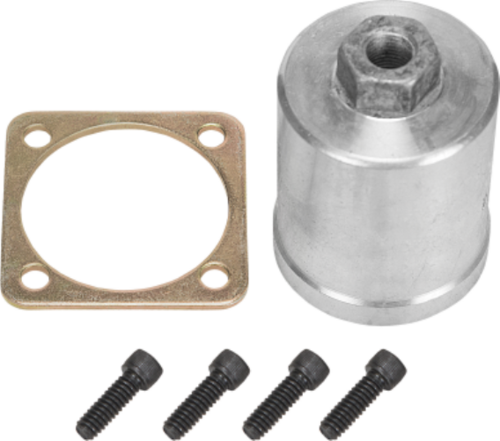

Thru Shaft Kit LPK 2516

Price 390 INR / Set

Minimum Order Quantity : 1 Set

Working Life : Up to 3 Years

Product Type : THRU SHAFT NUT

For Use In : LPK 2516 Vehicle Axle

Material : Alloy Steel

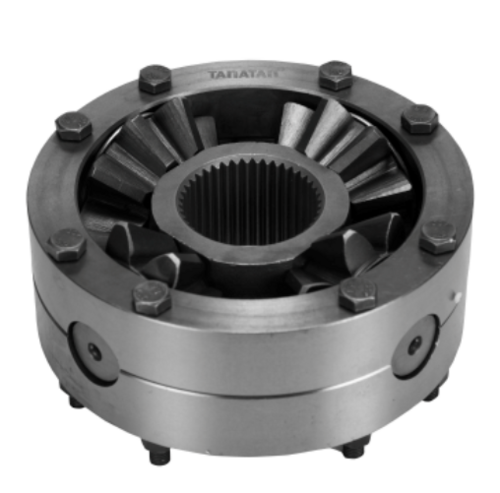

Nest Assembly (41 Teeth) LPK 2516

Price 7875 INR / Piece

Minimum Order Quantity : 1 Piece

Working Life : Long Life Over 80,000 km

Product Type : PINION NUT

For Use In : Heavy Duty Commercial Vehicle Transmission

Material : Alloy Steel

Input Shaft Oil Seal LPK 2516

Price 220 INR / Piece

Minimum Order Quantity : 1 Piece

Working Life : 30,000 Hours

Product Type : OIL SEAL

For Use In : Input Shaft LPK 2516

Material : Rubber

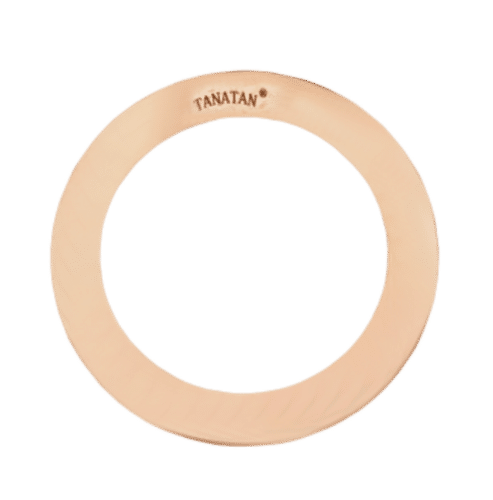

Input Shaft Washer 2518/4923

Price 1075 INR / Piece

Minimum Order Quantity : 1 Piece

Working Life : Up to 100,000 km

Product Type : INPUT SHAFT WASHER

For Use In : Gearbox / Transmission Assembly

Material : High Grade Steel

Send Inquiry

Send Inquiry