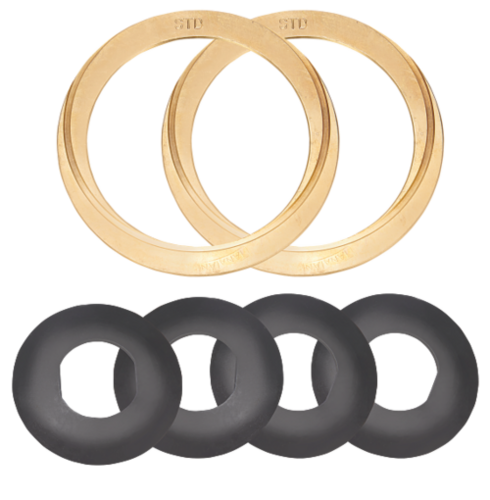

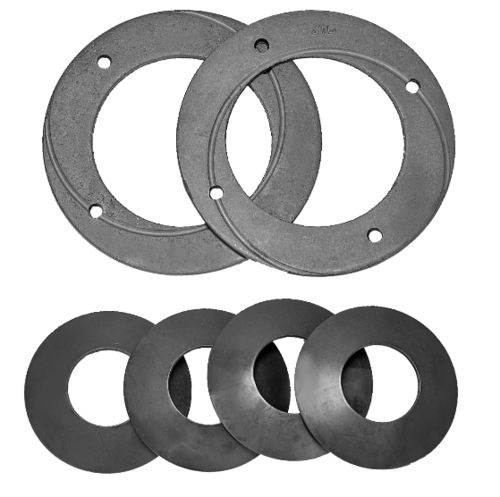

डिफà¥à¤°à¤¨à¥à¤¶à¤¿à¤¯à¤² सà¥à¤ªà¤¾à¤¯à¤¡à¤° वà¥à¤¶à¤° (2

Price 540 INR/ Set

MOQ : 1 Set

डिफà¥à¤°à¤¨à¥à¤¶à¤¿à¤¯à¤² सà¥à¤ªà¤¾à¤¯à¤¡à¤° वà¥à¤¶à¤° (2 Specification

- गंज प्रतिरोधक

- Yes, due to surface treatment

- कनेक्टिंग प्रकार

- Press fitted

- वजन

- Approx. 25 g

- रंग

- Metallic (Silver/Grey)

- ऑपरेटिंग सिस्टिम

- Mechanical interface

- वंगण प्रकार

- Grease lubricated

- मध्ये वापरासाठी

- Automotive differential assembly

- पृष्ठभाग उपचार

- Phosphated and oiled

- तापमान श्रेणी

- -40°C to +120°C

- पद्धत

- CNC Machined

- कार्यरत जीवन

- > 100,000 km

- आकारमान (एल* प* एच)

- Outer Diameter: 55 mm, Inner Diameter: 32 mm, Thickness: 2.5 mm

- वाहनाचा प्रकार

- Commercial and passenger vehicles

- ध्वनी पातळी

- < 25 dB under normal operation

- उत्पादनाचा प्रकार

- Differential Spider Washer (2nd O/S)

- आकार

- 2nd Oversize

- साहित्य

- High-grade alloy steel

- लोड क्षमता

- Suitable up to 5 Ton axle load

- मॉडेल नं

- DSW-2OS

- भाग प्रकार

- Differential washer

- समाप्त

- Smooth precision-ground

About डिफà¥à¤°à¤¨à¥à¤¶à¤¿à¤¯à¤² सà¥à¤ªà¤¾à¤¯à¤¡à¤° वà¥à¤¶à¤° (2

Get your axle assemblies performing at an unparalleled level with the acclaimed Differential Spider Washer (2nd O/S). Crafted from high-grade alloy steel and precision CNC-machined for esteemed automotive applications, this affordable washer ensures stellar operation under lofty axle loads up to 5 tons. Its impact resistance, burr-free edges, and induction-hardened structure deliver unmatched reliability and extended service life above 100,000 km. Available for OEM replacement, each washer is securely packed and instantly shipped, making it ideal for commercial and passenger vehicles across India. Custom options on bulk orders are also readily accessible.

Versatile Automotive Use and Wide Application

The Differential Spider Washer (2nd O/S) is primarily used as a critical component in automotive differential assemblies, especially for commercial and passenger vehicles. Its flat, precision-ground shape allows for seamless mounting between spiders and differentials, ensuring optimal gear alignment. Besides its main usage in differential gear systems, it is also adaptable for other high-load mechanical interfaces that require precise spacing and enhanced durability, making it a trusted choice among OEM, aftermarket, and bulk customizations.

Efficient Supply Chain and Sample Availability

Each Differential Spider Washer (2nd O/S) is available for prompt shipment, with significant supply ability managed by leading dealers, exporters, and wholesalers in India. Sample units can be provided upon request to ensure suitability before largescale commitment. Products are dispatched from major Indian FOB ports, minimizing extraneous expenditure. With a competitive asking price per unit and reliable packaging options, these washers are shipped rapidly for urgent requirements or scheduled orders.

Versatile Automotive Use and Wide Application

The Differential Spider Washer (2nd O/S) is primarily used as a critical component in automotive differential assemblies, especially for commercial and passenger vehicles. Its flat, precision-ground shape allows for seamless mounting between spiders and differentials, ensuring optimal gear alignment. Besides its main usage in differential gear systems, it is also adaptable for other high-load mechanical interfaces that require precise spacing and enhanced durability, making it a trusted choice among OEM, aftermarket, and bulk customizations.

Efficient Supply Chain and Sample Availability

Each Differential Spider Washer (2nd O/S) is available for prompt shipment, with significant supply ability managed by leading dealers, exporters, and wholesalers in India. Sample units can be provided upon request to ensure suitability before largescale commitment. Products are dispatched from major Indian FOB ports, minimizing extraneous expenditure. With a competitive asking price per unit and reliable packaging options, these washers are shipped rapidly for urgent requirements or scheduled orders.

FAQs of Differential Spider Washer (2nd O/S):

Q: How does the Differential Spider Washer (2nd O/S) enhance axle durability?

A: The washers high-grade alloy steel, induction hardening, and precision machining provide superior impact resistance and load-bearing capabilities, minimizing wear and tear and extending axle service life.Q: What is the installation process for this washer?

A: The washer is press fitted and sandwiched precisely between the spider and differential gears, ensuring stable alignment and low maintenance with periodic lubrication.Q: When should the Differential Spider Washer (2nd O/S) be replaced?

A: Replacement is typically recommended during routine differential servicing, especially if excessive wear, noise, or play is detected within the axle assembly.Q: Where can I use this washer besides standard differentials?

A: While specially designed for automotive differential assemblies, its robust construction allows usage in other mechanical interfaces demanding high impact resistance and precise spacing.Q: What are the primary benefits of choosing this washer for differential applications?

A: Key benefits include prolonged working life, unparalleled strength under lofty loads, corrosion resistance, smooth edges, low maintenance, and quick adaptability to OEM requirements.

Tell us about your requirement

Price: Â

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

मोबाईल number

Email

अधिक Products in स्पायडर वॉशर सेट Category

डिफरन्शियल स्पायडर वॉशर (9 व्या ओ/एस)

मापनाचे एकक : सेट/सेट

किमान ऑर्डरची मात्रा : 1

किंमत किंवा किंमत श्रेणी : INR

किंमत एकक : सेट/सेट

उत्पादनाचा प्रकार : Differential Spider Washer

आकारमान (एल* प* एच) : Outer Diameter: 70 mm, Inner Diameter: 30 mm, Thickness: 2.5 mm

शॅकल किट एफ-आर

मापनाचे एकक : तुकडा/तुकडे

किमान ऑर्डरची मात्रा : 100

उत्पादनाचा प्रकार : Shackle

आकारमान (एल* प* एच) : मिलीमीटर (मिमी)

भिन्न कोळी वॉशर (एसटीडी)

मापनाचे एकक : सेट/सेट

किमान ऑर्डरची मात्रा : 1

किंमत किंवा किंमत श्रेणी : INR

किंमत एकक : सेट/सेट

उत्पादनाचा प्रकार : SPIDER WASHER

भिन्न स्पायडर वॉशर 1ST ओ एस अल 3516 2518

मापनाचे एकक : सेट/सेट

किमान ऑर्डरची मात्रा : 1

किंमत किंवा किंमत श्रेणी : INR

किंमत एकक : सेट/सेट

उत्पादनाचा प्रकार : SPIDER WASHER

चौकशी पाठवा

चौकशी पाठवा